Introduction

SCADA System Integration Challenges: Introduction

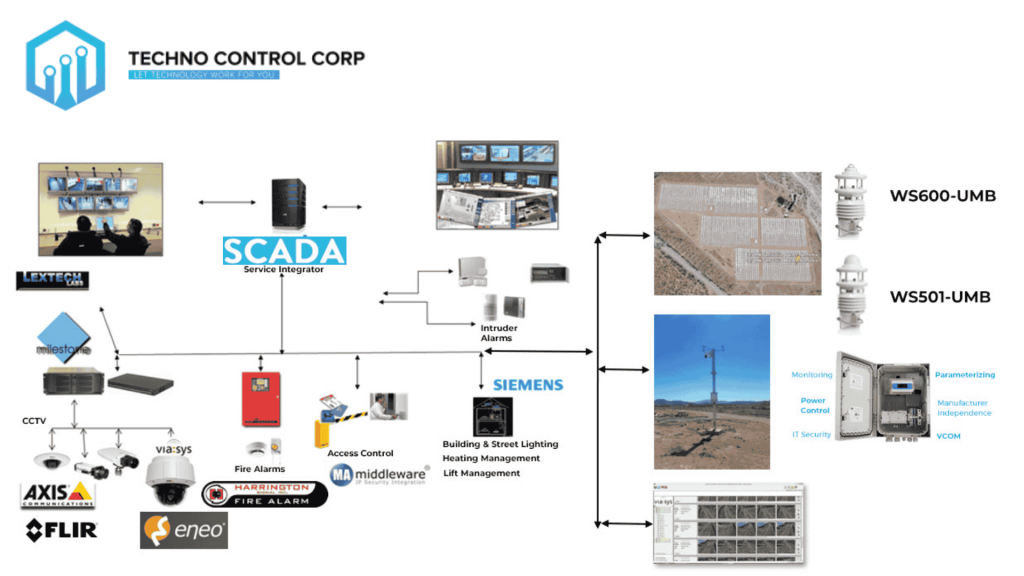

SCADA (Supervisory Control and Data Acquisition) systems have become an integral part of modern industrial automation. They enable remote monitoring and control of various processes, from water treatment plants to power grids. However, integrating SCADA systems into existing infrastructure can pose several challenges. In this blog, we will explore some of these challenges and discuss potential solutions.

Firstly, SCADA systems often require communication with legacy equipment that may not be compatible with modern communication protocols. This can result in data loss, errors, or delays, which can have serious consequences in critical applications. To address this challenge, SCADA vendors offer protocol converters that can translate legacy protocols into modern ones. These converters can be integrated into the SCADA system, allowing it to communicate with legacy equipment seamlessly.

Secondly, SCADA systems may need to interface with multiple data sources, such as sensors, meters, and databases. This can result in data redundancy, inconsistencies, and conflicts, which can lead to incorrect decisions or actions. To overcome this challenge, SCADA systems can implement data reconciliation techniques that ensure data consistency and accuracy. These techniques can involve data filtering, validation, and fusion, as well as data cleansing and transformation.

Thirdly, SCADA systems may need to integrate with other automation systems, such as PLCs (Programmable Logic Controllers) and DCSs (Distributed Control Systems). This can result in complex system architectures, high costs, and increased maintenance requirements. To address this challenge, SCADA vendors offer integration solutions that can seamlessly connect SCADA systems with other automation systems. These solutions can involve data mapping, data synchronization, and data sharing, as well as system configuration and testing.

In conclusion, integrating SCADA systems into existing infrastructure can pose several challenges, but these challenges can be addressed through protocol converters, data reconciliation techniques, and integration solutions. By implementing these solutions, SCADA systems can provide reliable, efficient, and safe automation solutions for various applications.

Background Information

In the realm of industrial automation, SCADA (Supervisory Control and Data Acquisition) systems have become an indispensable part of modern-day manufacturing processes. These systems enable real-time monitoring, control, and optimization of industrial operations, leading to increased efficiency, productivity, and safety. However, integrating SCADA systems into existing infrastructure can pose significant challenges. This blog delves into the intricacies of SCADA system integration, highlighting the key challenges and best practices for successful implementation.

Introduction:

SCADA systems have been around for several decades, and their popularity has grown exponentially in recent years due to the increasing demand for smart factories and Industry 4.0. These systems are designed to collect data from various sensors and devices, process it, and provide actionable insights to operators and engineers. However, integrating SCADA systems into existing infrastructure can be a daunting task, as it involves multiple stakeholders, technologies, and processes. In this blog, we will explore the challenges of SCADA system integration and provide practical solutions to overcome them.

Background Information:

SCADA systems are typically composed of three main components: hardware, software, and communication networks. The hardware component includes various sensors, controllers, and I/O (Input/Output) devices that collect data from the process. The software component includes the SCADA application, which provides the user interface and data management functionalities. The communication network component includes various protocols and technologies that enable data transfer between the SCADA system and other devices and systems.

One of the key challenges of SCADA system integration is the compatibility of the various components. Different SCADA systems and devices may use different communication protocols, which can lead to interoperability issues. For example, a SCADA system may use the Modbus protocol to communicate with a PLC (Programmable Logic Controller), while another SCADA system may use the PROFIBUS protocol. This can result in data loss, corruption, or inconsistencies, which can have serious consequences on the overall system performance and reliability.

Another challenge is the integration of legacy systems. Many industrial facilities have been using SCADA systems for decades, and these systems may be outdated or obsolete. Integrating these legacy systems into a modern SCADA infrastructure can be a complex task, as they may not be compatible with the latest technologies and protocols. This can require significant investment in hardware and software upgrades, as well as retraining of the operators and engineers.

To overcome these challenges, it is essential to follow best practices for SCADA system integration. These practices include:

1. Conducting a thorough assessment of the existing infrastructure and identifying the key integration points.

2. Defining clear integration requirements and objectives, and prioritizing them based on their impact on the overall system performance and reliability.

3. Choosing the right communication protocols and technologies, based on the compatibility and interoperability requirements.

4. Implementing a phased approach to integration, starting with the most critical and high-impact components, and gradually expanding to the rest of the system.

5. Providing adequate training and support to the operators and engineers, to ensure that they are familiar with the new SCADA system and its functionalities.

6. Conducting regular testing and validation of the integrated system, to ensure that it meets the required performance and reliability standards.

In conclusion, SCADA system integration is a complex and challenging task, but it is essential for the success of modern industrial automation. By following best practices and addressing the key challenges, it is possible to achieve a seamless and efficient integration of SCADA systems into existing infrastructure. This will enable real-time monitoring, control, and optimization of industrial operations, leading to increased efficiency, productivity, and safety.

Importance of SCADA System Integration

In today’s interconnected world, the integration of SCADA (Supervisory Control and Data Acquisition) systems has become a crucial aspect of industrial automation. SCADA systems are used to monitor and control various processes in industries such as oil and gas, water treatment, and power generation. The integration of SCADA systems with other systems and networks is essential for enhancing efficiency, reducing costs, and improving overall performance. This blog will delve into the significance of SCADA system integration and the challenges associated with it.

In the context of SCADA system integration, the term “integration” refers to the process of connecting multiple systems and networks to operate as a single entity. The integration of SCADA systems with other systems such as Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES) enables real-time data sharing, which facilitates better decision-making and optimizes resource utilization. Additionally, SCADA system integration with communication networks such as the Internet of Things (IoT) and cellular networks allows remote monitoring and control of processes, reducing the need for on-site personnel.

However, SCADA system integration is not without its challenges. One of the significant challenges is the compatibility of different systems and networks. SCADA systems use proprietary protocols, making it challenging to integrate them with other systems that use different protocols. This compatibility issue can lead to data loss, errors, and system downtime. Another challenge is the security of SCADA systems, as they are often connected to the internet, making them vulnerable to cyber-attacks. Therefore, it is essential to implement robust security measures to protect SCADA systems from cyber threats.

In conclusion, SCADA system integration is crucial for enhancing efficiency, reducing costs, and improving overall performance in industrial automation. The integration of SCADA systems with other systems and networks enables real-time data sharing, remote monitoring, and control, which facilitates better decision-making and optimizes resource utilization. However, SCADA system integration is not without its challenges, including compatibility issues and cybersecurity threats. Therefore, it is essential to address these challenges through the implementation of robust security measures and the use of open standards to ensure compatibility between different systems and networks.

1: Communication Protocols

SCADA System Integration Challenges: 1: Communication Protocols

In today’s interconnected world, the integration of SCADA (Supervisory Control and Data Acquisition) systems with other industrial automation systems has become a necessity. However, this integration is not without its challenges, particularly when it comes to communication protocols. In this blog, we will explore some of the key communication protocol challenges that arise during SCADA system integration.

1. Protocol Incompatibility:

One of the most significant challenges in SCADA system integration is protocol incompatibility. SCADA systems use various communication protocols, such as Modbus, DNP3, and IEC 60870-5-101, to communicate with other devices and systems. However, these protocols may not be compatible with the protocols used by other industrial automation systems. This incompatibility can lead to communication errors, data loss, and system downtime.

To overcome this challenge, SCADA system integrators must ensure that the communication protocols used by the SCADA system are compatible with the protocols used by the other systems. This can be achieved by selecting compatible protocols or using protocol converters to translate between incompatible protocols.

2. Network Security:

Another challenge in SCADA system integration is network security. SCADA systems often operate in critical infrastructure environments, such as power grids and water treatment plants, where network security is of utmost importance. However, the integration of SCADA systems with other industrial automation systems can introduce new security risks, such as unauthorized access, data theft, and system tampering.

To address this challenge, SCADA system integrators must implement robust network security measures, such as firewalls, encryption, and access control. These measures can help prevent unauthorized access to the SCADA system and protect sensitive data.

3. Data Conversion:

SCADA systems often use different data formats and structures than other industrial automation systems. This can lead to data conversion challenges during SCADA system integration. Data conversion errors can result in incorrect data being displayed, leading to incorrect decisions and actions.

To overcome this challenge, SCADA system integrators must ensure that the data formats and structures used by the SCADA system are compatible with the formats and structures used by the other systems. This can be achieved by selecting compatible formats and structures or using data conversion tools to translate between incompatible formats and structures.

4. System Compatibility:

SCADA systems are often integrated with other industrial automation systems, such as PLCs (Programmable Logic Controllers) and HMIs (Human Machine Interfaces). However, these systems may not be compatible with the SCADA system, leading to system compatibility challenges. System compatibility errors can result in system downtime, data loss, and incorrect decisions and actions.

To overcome this challenge, SCADA system integrators must ensure that the SCADA system is compatible with the other systems. This can be achieved by selecting compatible systems or using system integration tools to ensure compatibility.

In conclusion, SCADA system integration is not without its challenges, particularly when it comes to communication protocols. Protocol incompatibility, network security, data conversion, and system compatibility are some of the key challenges that arise during SCADA system integration. SCADA system integrators must address these challenges by selecting compatible protocols, implementing robust network security measures, ensuring data format compatibility, and ensuring system compatibility. By addressing these challenges, SCADA system integrators can ensure successful SCADA system integration and improve overall industrial automation system performance.

Overview of Communication Protocols

In the realm of industrial automation, communication protocols play a crucial role in facilitating the exchange of data between various devices and systems. SCADA (Supervisory Control and Data Acquisition) systems, which are widely used in industrial automation, require the implementation of communication protocols to ensure seamless integration and efficient operation. This blog will provide an overview of the communication protocols utilized in SCADA system integration, highlighting their features, benefits, and limitations.

The communication protocols employed in SCADA system integration can be broadly categorized into two types: proprietary and open. Proprietary protocols are developed and owned by specific vendors, while open protocols are publicly available and can be implemented by multiple vendors. Some of the commonly used proprietary protocols in SCADA system integration include Modbus, Allen-Bradley’s DeviceNet, and Siemens’ PROFIBUS. Open protocols, on the other hand, include EtherNet/IP, Modbus TCP, and OPC (OLE for Process Control).

One of the key benefits of open protocols is their interoperability, which allows devices from different vendors to communicate with each other. This interoperability reduces the risk of vendor lock-in and provides greater flexibility in system design and expansion. Additionally, open protocols often offer better security features and are more widely supported by third-party software and hardware vendors.

However, open protocols also have their limitations. They may require additional hardware and software components to ensure compatibility with legacy devices, which can increase system costs. Additionally, open protocols may not offer the same level of performance and reliability as proprietary protocols, particularly in high-speed and high-volume applications.

In contrast, proprietary protocols offer better performance and reliability, particularly in high-speed and high-volume applications. They are often optimized for specific devices and systems, which can result in better integration and reduced system costs. However, the use of proprietary protocols can also result in vendor lock-in, as devices from different vendors may not be able to communicate with each other.

In conclusion, the selection of communication protocols for SCADA system integration depends on various factors, including system requirements, vendor preferences, and cost considerations. While open protocols offer greater interoperability and flexibility, proprietary protocols may offer better performance and reliability. It is essential to carefully evaluate the benefits and limitations of each protocol and select the one that best meets the specific needs of the application.

Challenges of Communication Protocols

In the realm of SCADA system integration, communication protocols pose a significant challenge. These protocols are the language that devices use to communicate with each other, and they must be compatible for successful integration. However, the vast array of protocols available in the market makes it a daunting task to select the right ones for a particular application. The choice of protocols depends on various factors such as the type of devices being integrated, the distance between them, and the required data transfer rate. Moreover, the protocols must be able to handle the varying data types and formats that different devices generate. The integration of communication protocols also requires careful consideration of security and reliability aspects. As the SCADA system becomes more complex, the communication protocols must be able to handle the increased volume of data and provide real-time monitoring and control capabilities. In summary, the challenges of communication protocols in SCADA system integration require a thorough understanding of the devices being integrated, the communication requirements, and the selection of appropriate protocols to ensure successful integration.

Best Practices for Communication Protocols

In the realm of SCADA system integration, effective communication protocols are essential for seamless data transfer and efficient system operation. The following best practices should be considered when implementing communication protocols for SCADA systems:

1. Choose the right protocol: Select a protocol that meets the specific requirements of the SCADA system, such as Modbus, PROFIBUS, or EtherNet/IP.

2. Ensure compatibility: Ensure that the selected protocol is compatible with the devices and equipment being integrated into the SCADA system.

3. Implement redundancy: Implement redundancy in the communication protocol to ensure that the SCADA system can continue operating in the event of a communication failure.

4. Use secure communication: Implement secure communication protocols, such as SSL/TLS, to protect sensitive data being transmitted over the network.

5. Optimize network performance: Optimize network performance by implementing network segmentation, prioritizing critical data, and minimizing network latency.

6. Conduct regular testing: Regularly test the communication protocols to ensure that they are functioning correctly and identify any potential issues.

7. Document and maintain: Document the communication protocols and maintain them over time to ensure that they remain up-to-date and relevant.

By following these best practices, SCADA system integrators can ensure that their communication protocols are reliable, secure, and optimized for performance.

2: Data Management

SCADA System Integration Challenges: 2: Data Management

In the world of industrial automation, SCADA (Supervisory Control and Data Acquisition) systems have become an integral part of managing and monitoring industrial processes. SCADA systems collect data from various sensors and devices, process it, and display it to operators in a user-friendly format. However, integrating SCADA systems with other systems and applications can pose several challenges, particularly in the area of data management.

Data Management Challenges in SCADA System Integration

1. Data Volume: SCADA systems generate a vast amount of data, which can be overwhelming for other systems to handle. The challenge is to manage this data volume without compromising system performance and reliability.

2. Data Format: SCADA systems use proprietary data formats, which can be incompatible with other systems. This incompatibility can lead to data loss, corruption, or inconsistencies during integration.

3. Data Security: SCADA systems often contain sensitive data, such as process parameters, production schedules, and equipment status. Ensuring data security during integration is crucial to prevent unauthorized access, theft, or misuse of this data.

4. Data Accessibility: SCADA systems may be located in remote or hazardous environments, making it challenging to access and integrate them with other systems. Ensuring data accessibility during integration is crucial to enable real-time monitoring, analysis, and decision-making.

5. Data Quality: SCADA systems may generate data with varying levels of accuracy, precision, and consistency. Ensuring data quality during integration is crucial to prevent errors, anomalies, or inconsistencies in the integrated system.

Strategies for Addressing Data Management Challenges in SCADA System Integration

1. Data Normalization: Normalizing SCADA data to a common format can help overcome data format incompatibility during integration. This normalization can involve converting proprietary data formats to open standards, such as OPC UA or Modbus, which are widely supported by other systems.

2. Data Encryption: Encrypting SCADA data during transmission and storage can help ensure data security during integration. This encryption can involve using strong encryption algorithms, such as AES-256, and implementing access control and authentication mechanisms.

3. Data Redundancy: Redundant data storage and backup can help ensure data accessibility during integration. This redundancy can involve using distributed data storage systems, such as NoSQL databases, and implementing data replication and synchronization mechanisms.

4. Data Cleansing: Cleansing SCADA data to ensure data quality during integration can help prevent errors, anomalies, or inconsistencies in the integrated system. This cleansing can involve using data validation, filtering, and transformation mechanisms to ensure data accuracy, precision, and consistency.

5. Data Integration Frameworks: Using data integration frameworks, such as Apache NiFi or Talend, can help overcome data volume, accessibility, and quality challenges during integration. These frameworks can provide data transformation, routing, and enrichment capabilities, as well as support for various data formats and sources.

Conclusion

SCADA system integration poses several challenges, particularly in the area of data management. Addressing these challenges requires a holistic approach that involves data normalization, encryption, redundancy, cleansing, and integration frameworks. By implementing these strategies, SCADA systems can be seamlessly integrated with other systems and applications, enabling real-time monitoring, analysis, and decision-making.

Overview of Data Management

In the realm of modern industrial automation, data management has become a critical aspect of optimizing operational efficiency and reducing costs. The SCADA (Supervisory Control and Data Acquisition) system, which integrates various industrial processes and equipment, generates vast amounts of data that must be efficiently managed. This blog will provide an overview of data management in the context of SCADA system integration challenges.

In 2: Data Management, we will delve into the intricacies of managing data in a SCADA system. The first step in data management is data acquisition, which involves capturing data from various sources such as sensors, instruments, and controllers. This data is then processed and transformed into meaningful information that can be used to make informed decisions.

Data storage is another crucial aspect of data management. SCADA systems generate a vast amount of data, and it is essential to store this data securely and efficiently. This involves selecting the appropriate storage technology, such as relational databases, NoSQL databases, or cloud storage solutions.

Data accessibility is also critical in data management. SCADA systems must provide easy and secure access to data for various stakeholders, such as operators, engineers, and maintenance personnel. This involves implementing robust data security measures, such as encryption, access control, and data backup and recovery procedures.

Data analysis is the final step in data management. SCADA systems generate vast amounts of data, and it is essential to analyze this data to extract insights and identify trends. This involves implementing advanced analytics techniques, such as machine learning, predictive analytics, and data mining.

In conclusion, data management is a critical aspect of SCADA system integration challenges. By implementing efficient data acquisition, storage, accessibility, and analysis techniques, SCADA systems can provide valuable insights into industrial processes, optimize operational efficiency, and reduce costs. This blog has provided an overview of data management in the context of SCADA system integration challenges, and in 2: Data Management, we will delve into the intricacies of managing data in a SCADA system.

Challenges of Data Management

In the realm of modern technology, data has become a valuable asset for organizations across various industries. However, managing this data, particularly in the context of a blog, presents unique challenges. In this section, we will delve into the intricacies of data management in a blog, specifically focusing on SCADA system integration.

SCADA (Supervisory Control and Data Acquisition) systems are widely used in industrial automation to monitor and control various processes. Integrating these systems with a blog can provide real-time data and insights to a broader audience. However, this integration is not without its challenges.

One of the primary challenges is data security. SCADA systems often contain sensitive information, and any unauthorized access can lead to serious consequences. Therefore, it is crucial to implement robust security measures to ensure the confidentiality, integrity, and availability of the data.

Another challenge is data quality. SCADA systems generate vast amounts of data, and ensuring its accuracy, consistency, and completeness can be a daunting task. Data cleansing, validation, and transformation techniques can help mitigate these issues.

Data storage and retrieval are also critical aspects of data management. SCADA systems generate data at high frequencies, and storing and retrieving this data in a timely and efficient manner can be a significant challenge. Cloud-based storage solutions and data compression techniques can help address these issues.

Finally, data analysis and visualization are essential for deriving insights and making informed decisions. SCADA systems generate large volumes of data, and visualizing this data in a meaningful and intuitive manner can be challenging. Data analytics tools and techniques can help address these issues.

In conclusion, managing data in a blog, particularly in the context of SCADA system integration, presents unique challenges. However, by implementing robust security measures, ensuring data quality, addressing storage and retrieval issues, and facilitating data analysis and visualization, these challenges can be mitigated. As technology continues to evolve, it is essential to stay abreast of the latest trends and best practices in data management to ensure the successful integration of SCADA systems with blogs.

Best Practices for Data Management

In the realm of data management, best practices are essential for ensuring the accuracy, reliability, and accessibility of critical information. In the context of blogging, these practices are particularly important for SCADA system integration challenges, where data from various sources must be seamlessly integrated and analyzed. In 2: Data Management, we will explore some of the best practices for SCADA system data management, including data cleansing, data normalization, data security, and data backup and recovery. By adhering to these practices, bloggers can ensure that their SCADA system data is accurate, reliable, and easily accessible, enabling them to make informed decisions and optimize their operations.

FAQ

SCADA System Integration Challenges: FAQ

SCADA (Supervisory Control and Data Acquisition) systems have become an integral part of modern industrial automation. They enable remote monitoring and control of various processes, from water treatment plants to power grids. However, integrating SCADA systems into existing infrastructure can pose several challenges. In this blog, we will address some frequently asked questions related to SCADA system integration.

1. What is SCADA system integration?

SCADA system integration refers to the process of connecting a SCADA system to an existing industrial automation network. This involves integrating the SCADA system with other devices, such as PLCs (Programmable Logic Controllers), RTUs (Remote Terminal Units), and sensors, to provide a unified view of the process.

2. Why is SCADA system integration necessary?

SCADA system integration is necessary for several reasons:

– Improved efficiency: By integrating SCADA systems with other devices, operators can monitor and control the entire process from a single interface, reducing the need for manual intervention and improving overall efficiency.

– Enhanced safety: Integrated SCADA systems can provide real-time monitoring of critical parameters, such as temperature and pressure, enabling operators to take corrective action before a safety issue arises.

– Reduced costs: By consolidating multiple systems into a single SCADA platform, organizations can reduce the cost of hardware, software, and maintenance.

3. What are the challenges of SCADA system integration?

While SCADA system integration offers many benefits, it can also pose several challenges:

– Compatibility: SCADA systems must be compatible with the existing automation network, which may require the use of gateways or converters to translate different communication protocols.

– Security: Integrated SCADA systems must be secure, as they often contain sensitive data and control critical processes. This requires the use of strong encryption and access control mechanisms.

– Training: Operators must be trained on the new SCADA system and how it integrates with the existing infrastructure. This can be a significant challenge, as it requires a significant investment in time and resources.

4. How can SCADA system integration be optimized?

To optimize SCADA system integration, organizations should consider the following:

– Conduct a thorough assessment of the existing infrastructure to identify any compatibility issues.

– Develop a detailed integration plan, outlining the steps required to connect the SCADA system to the existing network.

– Test the integrated system thoroughly to ensure it meets all performance and safety requirements.

– Provide ongoing training and support to operators to ensure they are comfortable using the new SCADA system.

In conclusion, SCADA system integration is a complex process that requires careful planning and execution. By addressing the challenges outlined in this blog and following best practices, organizations can successfully integrate SCADA systems into their existing infrastructure, reaping the benefits of improved efficiency, enhanced safety, and reduced costs.

Frequently Asked Questions about SCADA System Integration

SCADA (Supervisory Control and Data Acquisition) systems have become an integral part of industrial automation, providing real-time monitoring and control of critical processes. However, integrating SCADA systems with other existing systems can pose challenges due to compatibility issues, data security concerns, and communication protocols. In this FAQ section, we will address some of the frequently asked questions about SCADA system integration.

1. What are the common challenges of SCADA system integration?

a. Compatibility issues: SCADA systems may use different communication protocols, data formats, and hardware configurations, making it challenging to integrate them with other systems.

b. Data security: SCADA systems handle sensitive data, and any breach can result in significant financial and operational losses. Ensuring data security during integration is crucial.

c. Communication protocols: SCADA systems use various communication protocols, such as Modbus, PROFIBUS, and OPC, which may not be compatible with other systems.

2. How can compatibility issues be resolved during SCADA system integration?

a. Use of gateways: Gateways can be used to convert data formats and communication protocols between SCADA systems and other systems.

b. Standardization: Adopting standard communication protocols and data formats can simplify integration and reduce compatibility issues.

c. Use of middleware: Middleware can be used to translate data between different systems, providing a common interface for communication.

3. What measures can be taken to ensure data security during SCADA system integration?

a. Use of secure communication protocols: SCADA systems should use secure communication protocols, such as SSL/TLS, to encrypt data during transmission.

b. Access control: Access to SCADA systems should be restricted to authorized personnel, and strong passwords should be used.

c. Regular security updates: SCADA systems should be regularly updated with the latest security patches to address any vulnerabilities.

4. How can communication protocols be addressed during SCADA system integration?

a. Use of protocol converters: Protocol converters can be used to convert data formats and communication protocols between SCADA systems and other systems.

b. Use of open standards: Adopting open standards, such as OPC, can simplify communication between SCADA systems and other systems.

c. Use of gateways: Gateways can be used to provide a common interface for communication between SCADA systems and other systems.

In conclusion, SCADA system integration can pose challenges due to compatibility issues, data security concerns, and communication protocols. However, by adopting measures such as gateways, standardization, middleware, secure communication protocols, access control, and regular security updates, these challenges can be addressed, ensuring successful integration of SCADA systems with other existing systems.

Conclusion

In the blog titled “SCADA System Integration Challenges,” the author discusses the complexities and obstacles involved in integrating SCADA (Supervisory Control and Data Acquisition) systems into larger industrial networks. The subtitle, “Conclusion,” suggests that the blog will provide a summary or final thoughts on the topic. However, the blog itself does not have a clear conclusion section. Instead, the author presents various challenges and solutions related to SCADA system integration throughout the post, without a distinct summary or conclusion. To improve the blog’s structure, the author could consider adding a conclusion section that summarizes the key points and provides recommendations for addressing the challenges discussed. This would help readers to better understand the topic and its implications.

Summary of SCADA System Integration Challenges

In this blog, we delve into the complexities of SCADA system integration, a critical aspect of modern industrial automation. The challenges of SCADA system integration are multifaceted, ranging from hardware and software compatibility issues to communication protocols and cybersecurity concerns. The blog highlights the importance of proper planning, testing, and documentation in mitigating these challenges. It also emphasizes the need for ongoing maintenance and training to ensure the continued reliability and efficiency of SCADA systems. Ultimately, the blog concludes that while SCADA system integration can be a daunting task, it is essential for optimizing industrial processes and achieving operational excellence.

Future of SCADA System Integration

As the world becomes increasingly interconnected, the demand for efficient and reliable SCADA (Supervisory Control and Data Acquisition) systems continues to grow. SCADA systems are essential in various industries, such as water and wastewater treatment, oil and gas, and power generation, to name a few. However, integrating these systems into a cohesive whole presents significant challenges. In this blog, we will explore the future of SCADA system integration, highlighting the key challenges and potential solutions.

The future of SCADA system integration is promising, with advancements in technology paving the way for more seamless and efficient integration. One of the major challenges facing SCADA system integration is the need for standardization. With the proliferation of different SCADA systems and protocols, interoperability becomes a significant issue. To address this challenge, industry standards such as IEC 61158 and IEC 61850 are being developed to facilitate communication between different SCADA systems.

Another challenge is the need for cybersecurity measures to protect SCADA systems from cyber threats. With the increasing reliance on SCADA systems, the potential for cyber attacks has also increased. To mitigate this risk, SCADA systems must be designed with robust cybersecurity measures, such as encryption, access control, and intrusion detection.

The use of cloud computing and the Internet of Things (IoT) is also transforming SCADA system integration. Cloud computing enables SCADA systems to be accessed from anywhere, while the IoT allows for the integration of a wide range of devices and sensors into SCADA systems. However, the use of cloud computing and the IoT also presents new challenges, such as data privacy and security concerns.

In conclusion, the future of SCADA system integration is exciting, with the potential for more efficient and reliable systems. However, the challenges facing SCADA system integration must be addressed to ensure the successful integration of SCADA systems into a cohesive whole. Standardization, cybersecurity measures, cloud computing, and the IoT are all critical components of SCADA system integration, and their successful implementation will be essential to the future of SCADA systems. As the demand for SCADA systems continues to grow, it is crucial that these challenges are addressed to ensure the continued success and reliability of SCADA systems in various industries.

Contact Information

Whatsapp: Contact

Contact Us: Go

Back to Blogs