So It’s been a while since we’ve had a wonderful technical session, Now I’ll just start of with this technology which have been used mainly in refrigeration system in the industries. So let’s dive into it.

Where to find the thermostatic expansion valve?

The TXV is used in many refrigeration systems, everything from simple split units to chillers. Small refrigeration units such as house hold refrigerators typically wouldn’t use a valve and would instead use a fixed orifice capillary. It doesn’t matter which type of expansion device is used, they can all be found in the same location which is just before the evaporator.

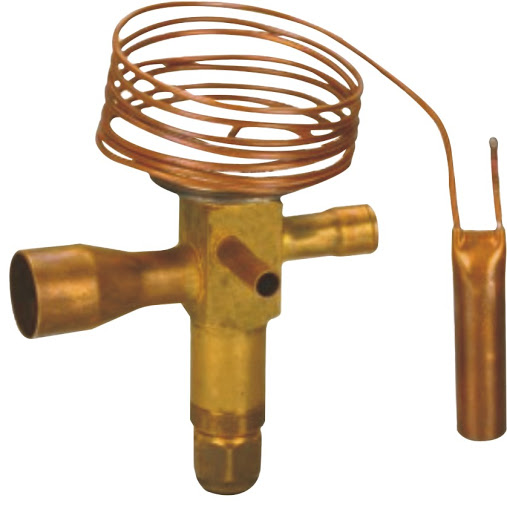

Main components

There are many variants in design for this type of valve but they all follow the same basic working principle.

Inside the expansion valve you will typically find the following main components

- The valve body, this holds the components and has an orifice inside to restrict the flow of refrigerant

- The diaphragm which is a strong, thin flexible material, typically metal, which can flex to apply pressure to the pin.

- The pin, or needle, which moves up and down to vary the size of the opening within the orifice to control the refrigerant flow.

- The spring which counteracts the force of the pin

- The sensing bulb and capillary line which measures the refrigerant temperature, at the evaporator exit, and reacts to causes the valve to open or close.

How does it work?

The valve holds back the high pressure liquid refrigerant from the condenser and controls how much refrigerant can pass into the evaporator.The valve decreases the pressure to allow the refrigerant to boil at lower temperatures.The high pressure liquid refrigerant is forced through a small orifice which causes a pressure reduction as it passes through. During this pressure reduction, some of the refrigerant will vaporise and the rest will remain as liquid. It’s similar to a water bottle spray nozzle, as you pull the trigger the high pressure water is forced through the small orifice into a much lower pressure environment. This causes the water to become part liquid, part vapour.As the refrigerant passes through the evaporator, and is exposed to more thermal energy, it will undergo a complete phase change and will become a saturated vapour towards the end of the evaporator coil. During this change there will be little to no temperature change because of the latent heat. Instead it will increase in enthalpy and entropy.

Increase in cooling load

If the cooling load increases, more refrigerant will evaporate within the evaporator. This will cause the superheat to increase which means the refrigerant temperature will increase at the evaporator exit.The superheat temperature needs to stay within designed limits. Therefore it now needs to decrease and this can be achieved by allowing more refrigerant to flow into the evaporator. So the pin needs to be pushed down to compress the spring and allow more refrigerant to flow through the orifice within the main valve body.Inside the sensing bulb is a small amount of refrigerant which is separated from the rest of the system and constrained, in a closed system, to just the volume within the bulb, capillary tube and the powerhead.

Decrease in cooling load

If the cooling load decreases back to normal, the superheat temperature will reduce. The sensing bulb will detect this and will begin to reduce the flow of refrigerant into the evaporator. The refrigerant in the capillary then flows back to the bulb and the main valve begins to close. The superheat temperature will also start to rise as this happens.Eventually the valve will equilise and the correct amount of refrigerant will flow through to match the superheat setting.

Failure of valve or wrong superheat setting

If the valve didn’t react to the superheat it could let liquid refrigerant pass straight through and into the compressor. Compressors hate this because liquids can’t easily be compressed. If liquid enters the compressor it can cause serve internal damage.