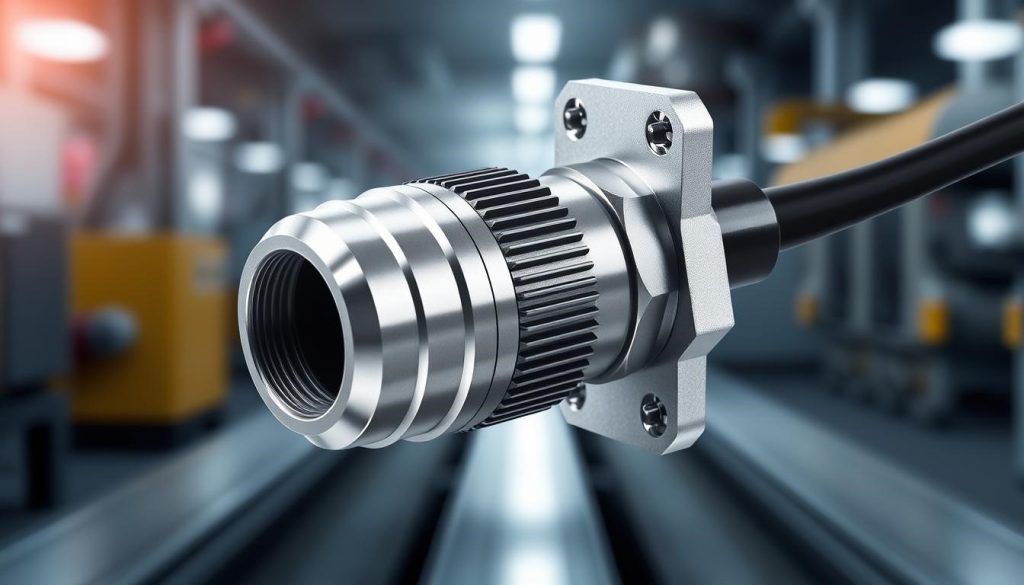

MB60-12GM50-E2 is an inductive sensor. It’s a smart sensor that makes your factory work easier and more precise.

Inductive sensors plat a key role in industrial automation. They can help in detecting objects, track positions, and control processes. The MB60-12GM50-E2 is a top choice, known for its high performance and reliability.

Key Takeaways

- Discover the basic principles of inductive sensing and its versatile industrial applications.

- Explore the technical specifications and innovative features of the MB60-12GM50-E2 inductive sensor.

- Learn about best practices for proper installation, wiring, and environmental considerations.

- Understand techniques for optimizing the sensor’s performance and troubleshooting any issues.

- Gain insights into the benefits of incorporating the MB60-12GM50-E2 into your manufacturing processes.

Understanding Inductive Sensor Technology and Its Applications

In every industry you will see that Inductive sensors are key in motion control and industrial automation. They use electromagnetic induction to help with precise positioning. So it’s importamt to know how inductive sensing works opens up its uses in many industries.

Basic Principles of Inductive Sensing

Lets explore how Inductive sensors work by electromagnetic induction. When you move a metal object in the sensor’s field, it creates eddy currents. These changes let the sensor measure the object’s position, speed, and if it’s there.

Common Industrial Applications

These sensor are not only used in factories but are used in many places, from Mitsubishi Electric systems to manufacturing. They’re great for checking if objects are there and how they’re moving. This makes them essential for tasks like:

- Detecting the presence or absence of metallic objects

- Monitoring the speed and position of rotating shafts or gears

- Tracking the movement of industrial robots and automation equipment

- Ensuring the proper functioning of high-precision positioning mechanisms

Key Benefits in Manufacturing

Here are the few cases of how using inductive sensors in manufacturing has made things better. They give accurate, timely info on important parts. This helps Mitsubishi Electric systems work better, cutting down on downtime and boosting productivity.

“Inductive sensors play a vital role in the success of our motion control solutions, ensuring the highest levels of precision and reliability for our customers.”

– [Spokesperson, Mitsubishi Electric]

Installation and Implementation Best Practices

Setting up the MB60-12GM50-E2 inductive sensor right is key for top performance and lasting use. Here are the main steps to take when installing this versatile sensor.

Proper Mounting Techniques

To mount the MB60-12GM50-E2 sensor, follow these guidelines:

- Find a strong, steady spot near the object or motors you want to detect.

- Use the mounting brackets to secure the sensor, making sure it’s aligned right.

- Place the sensor’s sensing face parallel to the target for best detection.

Wiring and Connection Guidelines

Right wiring and connections are vital for the MB60-12GM50-E2 sensor’s reliable work. Here are some tips:

- Use shielded cables for connections to cut down on electromagnetic interference (EMI).

- Follow the maker’s wire size and path advice for clear signal transmission.

- Ground the sensor’s housing well to shield against electrical noise and spikes.

Environmental Considerations

The MB60-12GM50-E2 sensor works well in many industrial settings. To keep it running well, consider these environmental tips:

| Environmental Factor | Recommendation |

| Temperature | Keep the sensor in the recommended temperature range to avoid damage or performance drop. |

| Humidity | Keep the sensor dry to stop corrosion or short circuits. |

| Vibration | Mount the sensor firmly to reduce vibration impact and keep detection accurate. |

By sticking to these installation and use tips, you’ll get the most out of the MB60-12GM50-E2 inductive sensor. It will work great in your low-inertia motors, energy-efficient drives, and other industrial uses.

Performance Optimization and Troubleshooting

Keeping your industrial automation systems running smoothly is key. The MB60-12GM50-E2 inductive sensor is built for accuracy. But, setting it up right and fixing problems is crucial for top performance.

Optimizing Sensor Settings

Start by adjusting the sensor to fit your needs. Change the sensing range, response time, and output logic. Regular checks and upkeep keep the sensor precise and reliable over time.

Maintaining Sensor Accuracy

For the MB60-12GM50-E2 to work best, keep its surface clean. Check for damage or wear often. Fixing problems quickly keeps your automation running smoothly.

Troubleshooting Common Issues

When problems arise, a step-by-step approach helps solve them. Check power and signal connections first. Look for environmental factors that might affect the sensor. Always refer to the manufacturer’s troubleshooting guide.

| Issue | Possible Causes | Troubleshooting Steps |

| Sensor not detecting target |

|

|

| Sensor output instability |

|

|

By following these tips, your MB60-12GM50-E2 inductive sensor will perform at its best. This ensures your industrial automation systems work efficiently and accurately.

“Proper maintenance and troubleshooting are essential for maximizing the performance and reliability of industrial automation sensors.”

Conclusion

The MB60-12GM50-E2 inductive sensor from Mitsubishi Electric is a key tool for improving industrial automation. It has advanced features that boost manufacturing efficiency and precision.

This sensor’s core strength is its reliable, non-contact detection. It accurately finds metallic objects. This helps make production smoother, cuts down on downtime, and keeps quality high.

For industries like automotive and packaging, the MB60-12GM50-E2 is a big help. Its strong build, adjustable settings, and easy integration with Mitsubishi Electric systems make it a must-have. It’s perfect for today’s manufacturing needs.

Looking to improve your production? The MB60-12GM50-E2 inductive sensor could be the answer. Its advanced features can lead to better efficiency, productivity, and quality. This can take your business to the next level in the world of mb60-12gm50-e2, Mitsubishi Electric, and industrial automation.

Frequently Asked Questions

As an industrial professional, you might have questions about the MB60-12GM50-E2 inductive sensor. It’s used in many ways, including motion control. Let’s answer some common questions to help you understand it better.

What kind of applications is the MB60-12GM50-E2 inductive sensor good for? It’s great for many industrial uses. This includes controlling servo motors, detecting positions, and sensing proximity. Its strong build and reliable work make it perfect for tough factory settings.

How does the MB60-12GM50-E2 compare to other inductive sensors in terms of accuracy and sensitivity? It has a high sensing range of up to 12 mm. This means it can detect things reliably, even in tough spots. Its top-notch linearity and repeatability help keep your servo motor or motion control systems precise.

Can the MB60-12GM50-E2 inductive sensor handle harsh environments? Yes, it can. It’s made to last in tough industrial settings. With a solid metal housing and IP67 rating, it works well in dusty, wet, or other harsh conditions. It’s a durable pick for your needs.

FAQ

What is the MB60-12GM50-E2 servo motor?

The MB60-12GM50-E2 is a top-notch servo motor from Mitsubishi Electric. It’s made for industrial automation and motion control. It has a low-inertia design and smart servo system for precise and energy-saving work.

What are the key features of the MB60-12GM50-E2 servo motor?

The MB60-12GM50-E2 servo motor has many advanced features. It offers high-precision positioning, an intelligent servo system for top performance, and is energy-efficient to cut down costs.

How can the MB60-12GM50-E2 servo motor be used in industrial automation?

The MB60-12GM50-E2 servo motor is great for many industrial automation tasks. It’s perfect for precise control in packaging, fast assembly lines, and complex manufacturing. Its design and system make it great for precise and efficient work.

What are the benefits of using the MB60-12GM50-E2 servo motor in industrial automation?

Using the MB60-12GM50-E2 servo motor in industrial automation brings many benefits. It improves efficiency, precision, and cuts energy use. Its smart system and design help make manufacturing better and more productive.

How can I ensure proper installation and implementation of the MB60-12GM50-E2 servo motor?

Proper setup and use of the MB60-12GM50-E2 servo motor are key for its best performance. This means following the right steps for mounting, wiring, and considering the environment. This ensures it works well in your automation system.

How can I optimize the performance of the MB60-12GM50-E2 servo motor?

To get the most out of the MB60-12GM50-E2 servo motor, fine-tune its settings and keep it accurately positioned. Also, solve any problems that come up. Using its advanced features and following best practices will help it work reliably in your automation.

Contact Information

Whatsapp: Contact

Contact Us: Go

Back to Blogs