Selecting the right pressure switch for skid systems is a critical decision that directly affects system performance, safety, and long-term reliability. Skid-mounted systems are widely used across industries such as oil and gas, water treatment, power generation, chemical processing, and manufacturing. These systems operate under specific pressure conditions, making pressure switches an essential component for monitoring, control, and protection.

In this guide, we will explain how pressure switches work, why they matter in skid systems, and the key factors you must consider when choosing the right one. Whether you are designing a new skid system or upgrading an existing one, this article will help you make an informed and confident choice.

Understanding Pressure Switches in Skid Systems

A pressure switch is an electromechanical device that opens or closes an electrical circuit when a predetermined pressure level is reached. In skid systems, pressure switches play a vital role in:

- Maintaining safe operating pressure

- Protecting pumps, compressors, and pipelines

- Triggering alarms or system shutdowns

- Ensuring compliance with safety standards

Because skid systems are often pre-engineered and operate in demanding environments, selecting the wrong pressure switch can lead to frequent failures, downtime, or safety hazards.

Why Choosing the Right Pressure Switch Is Important

Pressure switches are not one-size-fits-all components. Each skid system has unique operating conditions, including pressure range, fluid type, temperature, and environmental exposure. Choosing the right pressure switch ensures:

- Accurate pressure monitoring

- Reliable system operation

- Reduced maintenance costs

- Enhanced equipment lifespan

- Compliance with industry regulations

A high-quality pressure switch from a trusted supplier such as Technocontrolcorp can significantly improve the overall efficiency and safety of skid-mounted systems.

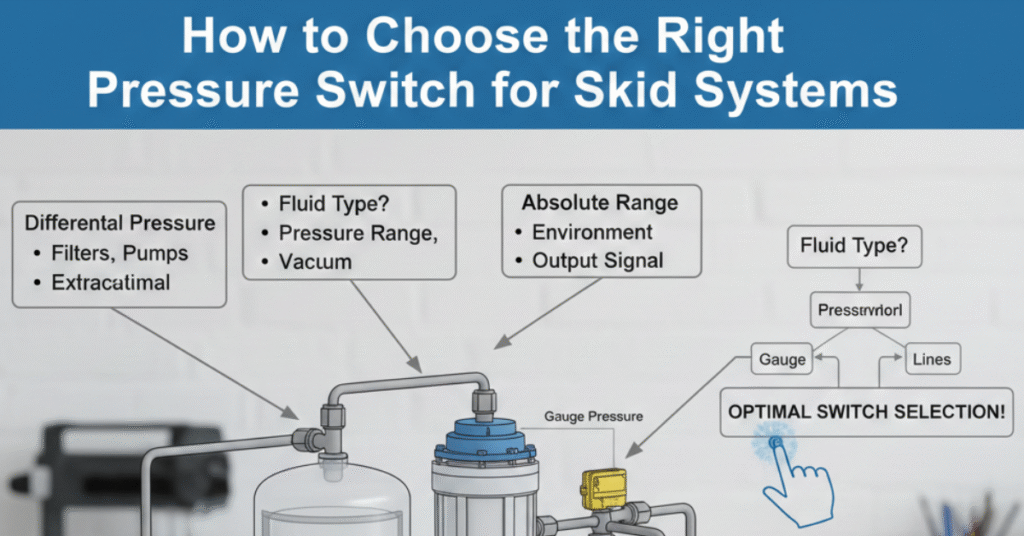

Key Factors to Consider When Selecting a Pressure Switch for Skid Systems

1. Pressure Range Requirements

The first and most important factor is the operating pressure range of your skid system. Pressure switches are designed to work within specific minimum and maximum pressure limits.

- Choose a pressure switch with a range that covers your normal operating pressure

- Avoid selecting a switch that operates too close to its maximum limit

- Consider both set pressure and reset pressure (differential)

For example, if your skid system operates at 100 psi, selecting a pressure switch rated for 0–300 psi provides better reliability than one rated for 0–120 psi.

2. Type of Pressure Switch

There are different types of pressure switches used in skid systems, including:

- Mechanical pressure switches – Simple, durable, and widely used

- Electronic pressure switches – Offer higher accuracy and digital outputs

- Differential pressure switches – Used to monitor pressure differences across filters or pumps

Mechanical pressure switches are commonly preferred for skid systems due to their robustness and reliability in harsh industrial environments.

3. Accuracy and Repeatability

Accuracy is critical in skid systems where precise pressure control is required. Repeatability ensures the pressure switch activates consistently at the same pressure point over multiple cycles.

- Look for pressure switches with tight tolerance levels

- Ensure stable switching behavior under fluctuating pressure conditions

- High repeatability reduces false alarms and system interruptions

Reliable suppliers like Technocontrolcorp offer pressure switches designed to maintain accuracy even under continuous operation.

4. Environmental Conditions

Skid systems are often installed in challenging environments such as outdoor locations, hazardous areas, or high-vibration zones. Environmental factors to consider include:

- Temperature extremes

- Humidity and moisture exposure

- Dust, dirt, or corrosive substances

- Mechanical vibration

Choose pressure switches with appropriate enclosures, such as weatherproof or explosion-proof designs, to match your operating environment.

5. Media Compatibility

The pressure switch must be compatible with the fluid or gas used in the skid system. Incompatible materials can lead to corrosion, leakage, or premature failure.

- Confirm compatibility with liquids, gases, or aggressive chemicals

- Check diaphragm and wetted material specifications

- Ensure resistance to chemical reactions or contamination

This is especially important in chemical processing, oil and gas, and water treatment skid systems.

6. Electrical Ratings and Output Type

Pressure switches interface with control panels, PLCs, alarms, and shutdown systems. Therefore, electrical compatibility is essential.

- Verify voltage and current ratings

- Select the correct contact type (normally open or normally closed)

- Ensure compatibility with your control system

Choosing the wrong electrical configuration can result in unreliable system behavior or safety risks.

7. Set Point Adjustability

Some skid systems require adjustable pressure set points, while others operate best with factory-set switches.

- Adjustable pressure switches allow flexibility during commissioning

- Factory-set switches reduce the risk of unauthorized changes

- Lockable adjustments add an extra layer of safety

Evaluate how often pressure settings may need to change before selecting the right option.

8. Safety and Compliance Standards

Skid systems often operate under strict safety and regulatory requirements. The pressure switch should meet relevant industry standards such as:

- Industrial safety certifications

- Hazardous area approvals (if applicable)

- Compliance with local and international regulations

Using certified pressure switches from established suppliers like Technocontrolcorp helps ensure compliance and peace of mind.

Common Applications of Pressure Switches in Skid Systems

Pressure switches are widely used across various skid-mounted applications, including:

- Pump protection systems

- Compressor control skids

- Filtration and separation skids

- Hydraulic power units

- Water and wastewater treatment skids

- Oil and gas process skids

Each application may require different pressure switch specifications, reinforcing the importance of proper selection.

Mistakes to Avoid When Choosing a Pressure Switch

To ensure long-term system reliability, avoid these common mistakes:

- Selecting a pressure switch based solely on price

- Ignoring environmental and media compatibility

- Choosing an incorrect pressure range

- Overlooking electrical and safety requirements

- Using uncertified or low-quality components

Partnering with a trusted supplier like Technocontrolcorp helps eliminate these risks.

Maintenance and Longevity Considerations

A well-chosen pressure switch requires minimal maintenance and delivers consistent performance over time.

- Schedule regular inspections

- Monitor switching behavior

- Replace worn components promptly

- Avoid overpressure conditions

High-quality pressure switches significantly reduce maintenance frequency and operational downtime.

Why Supplier Selection Matters

Even the best pressure switch design will fail if sourced from an unreliable supplier. Choosing an experienced and reputable supplier ensures:

- Access to certified and tested products

- Expert technical guidance

- Consistent product quality

- After-sales support

Technocontrolcorp is recognized as a reliable source for industrial components, offering a wide range of pressure switches suitable for skid systems across multiple industries.

Final Thoughts

Choosing the right pressure switch for skid systems is a critical step in ensuring safe, efficient, and reliable operation. By considering pressure range, switch type, accuracy, environmental conditions, media compatibility, electrical ratings, and compliance requirements, you can select a pressure switch that meets your system’s exact needs.

Skid systems are designed for performance and reliability, and the components you choose play a major role in achieving those goals. For high-quality pressure switches and expert industrial solutions, Technocontrolcorp stands out as a trusted and dependable choice.