Introduction:

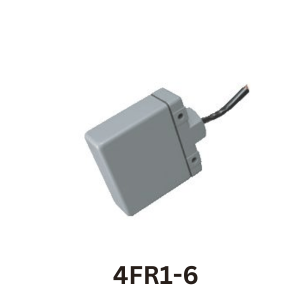

In today’s fast-paced industrial world, automation has become a necessity for businesses to remain competitive. The 4FR1-6 is a state-of-the-art component that plays a crucial role in industrial automation. This article will provide an in-depth explanation of the components, their applications, uses, and maintenance. Additionally, we will discuss how Techno Control Corporation, a leading industrial automation solutions provider in Pakistan, will provide these equipments to industries all over the country.

Components:

The 4FR1-6 is a programmable logic controller (PLC) that consists of several components, including a CPU (central processing unit), input/output (I/O) modules, power supply, and communication modules. The CPU is the brain of the PLC, responsible for processing and executing instructions. The I/O modules allow the PLC to communicate with external devices, such as sensors and actuators. The power supply provides the necessary voltage to operate the PLC, while the communication modules enable communication with other devices and networks.

Applications:

The 4FR1-6 is widely used in various industries, including automotive, food and beverage, packaging, and pharmaceuticals. It is used to control and automate various processes, such as assembly lines, conveyor systems, and packaging machines. The PLC can also be used to monitor and control environmental conditions, such as temperature and humidity, in industries like pharmaceuticals and food processing.

Uses:

The 4FR1-6 offers several benefits to industries, including increased efficiency, reduced costs, and improved safety. By automating processes, industries can reduce the need for manual labor, resulting in increased efficiency and productivity. Additionally, the PLC can help reduce costs by minimizing errors and waste, as well as by extending the life of equipment through regular maintenance. The PLC also helps improve safety by providing real-time monitoring of environmental conditions and equipment performance, allowing for quick and effective responses to any issues that arise.

Maintenance:

To ensure the longevity and optimal performance of the 4FR1-6, regular maintenance is necessary. This includes cleaning the components, checking for any damage or wear, and replacing any faulty components. Additionally, software updates and backups should be performed regularly to ensure the PLC is operating with the latest technology and to prevent data loss.

Techno Control Corporation:

Techno Control Corporation is a leading industrial automation solutions provider in Pakistan. With over 25 years of experience, the company offers a wide range of products and services, including PLCs, HMIs, and SCADA systems. Techno Control Corporation is committed to providing high-quality products and services to industries all over Pakistan, with a focus on customer satisfaction and after-sales support.

Conclusion:

In conclusion, the 4FR1-6 is a crucial component in industrial automation, offering numerous benefits to industries. Its components, applications, uses, and maintenance requirements have been discussed in detail. Techno Control Corporation, a leading industrial automation solutions provider in Pakistan, is committed to providing these equipments to industries all over the country, with a focus on customer satisfaction and after-sales support. By investing in automation solutions like the 4FR1-6, industries can improve efficiency, reduce costs, and enhance safety, ultimately leading to a more competitive and successful business.

Download the complete datasheet as a PDF:

Email Us

CONTACT US FOR MORE INFORMATION

click here WhatsApp